Down Quality Determining Factor 6. Turbidity

2019-06-13

At PRAUDEN, we inform consumers of the important factors that determine the quality of down via feature articles so that they can make informed decisions when purchasing down. Following on from ‘fat and oil’ in the last issue, in this issue, we will look at ‘turbidity’ as a factor for determining down quality.

See Down Quality Determining Factor 1. Content

See Down Quality Determining Factor 2. Fill Power

See Down Quality Determining Factor 3. Species Identification

See Down Quality Determining Factor 4. Black Point

See Down Quality Determining Factor 5. Oil & Fat

‘What is Turbidity’?

The degree of cloudiness of water is referred to as turbidity. Here, it is a test method by which turbidity is evaluated by dissolving the feathers in distilled water for the purpose of ascertaining the cleanliness of processed feathers. If there are many impurities, the visibility is low and the numerical value is low.

What Factors Affect Turbidity?

-State of the raw material: It depends on the processing condition of the collected raw material.

-Water quality: It depends on the type of water quality used and the amount of water used.

-Processing time and chemicals: The longer the processing time, the higher the turbidity and it is affected by the type and amount of chemicals used in processing.

-Storage period: If the feathers are stored for a long period of time, they become decayed and the turbidity value is lowered.

Turbidity Test Method (according to KS K 0820)

1. Sampling (same as other tests)

2. Test Methods

1) Add the sample to an Erlenmeyer flask and add 100mL of distilled water at 20°C until the sample is sufficiently wet, then add another 200mL of distilled water.

2) Shake for 45 minutes on a shaker.

3) Separate the down and suspension.

4) Fill a transparency meter with the filtered liquid and then discharge until the + mark on the bottom is clearly visible. The height of the suspension after discontinuance of discharge is indicated as the test result value.

3. Expression of Results

The average value of three test results is expressed as an integer in millimeters.

<Shaking – The plate on the top of the machine moves rapidly to the left and right.>

Is a Higher Turbidity Better?

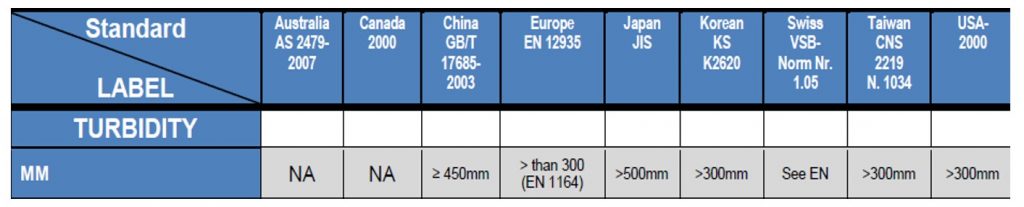

Turbidity standards differ slightly in each country, but it is judged that if it is above 300mm then there will be no problems using it in everyday life.

<Turbidity Test Standards of Each Country>

However, if the turbidity value is excessively high, this can also be a problem. In order to increase turbidity, chemicals with a strong chemical composition used during the washing process or washing for a long time may cause loss of components for maintaining the shape of the down, which may adversely affect the warmth of the down.

Turbidity is not a yardstick for better quality down, but should be approached as a test to confirm whether the minimum conditions are met.

By Oh Joon-jae, R&D Part, PRAUDEN