Down Quality Determining Factor 4. Black Point

2018-12-11

PRAUDEN features articles that introduce important factors that determine the quality of the down so that consumers can make informed purchases. Following ‘Species Identification’ of the last this issue, we are going to look at ‘Black Point.’

See Down Quality Determining Factor 1. Content

See Down Quality Determining Factor 2. Fill Power

See Down Quality Determining Factor 3. Species Identification

What is Black Point?

Down and feathers are commercially sold in white or grey. Black Point means feathers with deviating color, such as colors black, brown, golden and non-whites, from white down and feathers. (Chemically colored downs are not considered as Black Points.)

<White (Left) and Grey (Right) Down and Feathers>

<Black Points in White Down and Feathers>

Where do Black Points come from?

Color of down and feathers depend on demographic and geographical conditions and very largely by region and country. Dependant on such conditions, down and feathers are manifested in, among others, colors white, grey, brown.

<Canadian Geese (Left) and Polish Geese (Right)>

1) Factor of nature: Feathers of such white feather species as Canadian goose might locally be manifested with colors.

2) Factor of industry: Despite color classification in feather collecting process for uniform down and feather colors, some down and feathers mix to each other in post-slaughter washing processes.

How to test Black Points?

Color separation test (also referred to as black tip test) assesses the content (weight) of down and feathers of deviating colors in a given volume of samples and is performed as follows:

1. Sampling

1) (If relevant, open the sack and) Sample down and feathers from both top and middle layers.

2) Mix the samples in a conditioning box and stand until the weight is constant.

3) Sample again, this time from top, middle and bottom layers, by 5g per layer.

2. Identification Test

Use tweezers to separate from each other grey, grown and black down and feathers in a grading box and weigh (in milligrams).

(Chemically colored downs are not considered as Black Points.)

3. Result

The percentage of Black Points to the sample in terms of weight is rounded to, unless otherwise set forth, the nearest hundredth.

Why does Black Point matter?

Neither insulation nor decolorization explains reason of why Black Points matter as they do not affect heat preservation ability and decolorization in washing. However, Black Points matter when in white or bright color cloths made of thin materials as they are looked through sometimes, aesthetically affecting product’s quality.

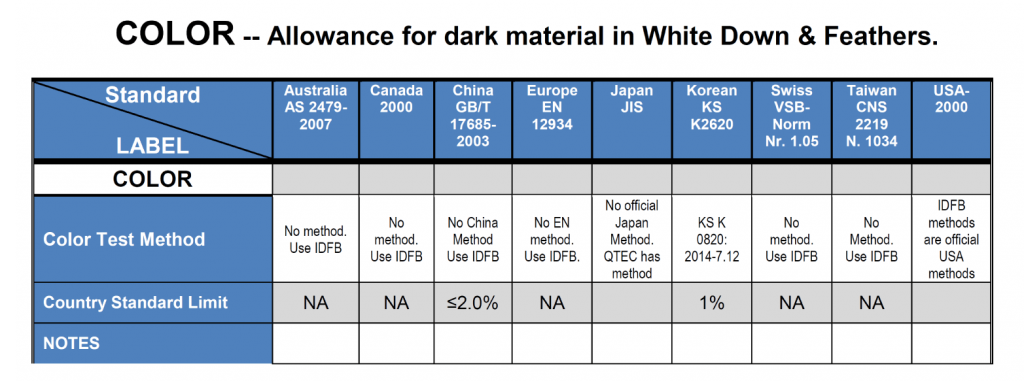

<Allowance in Down & Feathers Quality – Black Point>

The Korean Standards apply one of the most strict Black Point criteria, compared to other countries with less strict criteria or even devoid of the relevant criteria.

PRAUDEN Efforts

With white or light down jackets gaining popularity, PRAUDEN offers Pure White Down and Feathers under extreme flawlessness criteria 10 times as strict as the relevant Korea Standards.

How to choose down and feathers wisely

1. Make sure how clearly you can see through what’s under the bright, thin mockup fabric that is properly sampled for down-fabric-down structure of layers.

2. Do not omit visual inspection of the incoming down and feathers, and contact the supplier should there be any concern.

3. For see-through fabric, consult your supplier to optimize your order.

Remember, nothing’s 100% flawless in down and feathers that come from the nature. PRAUDEN’s ceaseless efforts, however, are making possible nearly flawless down and feathers by carefully controlling sourcing and production, which merchandisers and consumers should keep in mind to choose down and feathers wisely.

By Oh Jun-jae, R&D Part, PRAUDEN