Down Quality Determining Factor 1. Content

2018-04-09

Last winter, which recorded exceptionally cold weather, down material clothes, including long padded coats, gained tremendous popularity. Down clothing is the flagship of each brand in the winter season, and now it has become necessary to reserve down clothing for the winter. With so many down products coming out every season, consumers are becoming increasingly interested in the type and quality of products. In line with this trend, we will detail the factors that can affect the quality of the down clothing, as well as the methods used by PRAUDEN to check the down and the factors that determine the quality of down in order to help relevant industry professionals and consumers to make wise choices.

- Composition: Visual inspection on composition including down clusters, feathers, broken feathers, fiber, residues, etc. and finding the composition ratio

- Species Identification: Identifying goose down and duck down and measuring the mixing ratio using a microreader or microscope

- Fill Power: Checking bulkiness by measuring the volume of down and feathers of a constant weight

- Odor: Checking the existence of odor such as distinct stench of down and feathers, chemicals, etc.

- Oxygen Number: Inspecting the cleanliness of down and feathers by measuring the level of oxygen required for oxidizing impurities

- Oil & Fat: Inspecting if down and feathers contain a proper level of oil and fat by measuring the dry weight

- Turbidity: Determining the turbidity level by eluting down and feathers with distilled water in order to measure content of impurities such as dust

- Moisture Content: Measuring the moisture content of down and feathers

- Color Separation: Measuring the ratio of gray, brown, and black down and feathers to white down and feathers

<Korea Standard Down Quality Inspection List>

There are several items for down testing. There are some differences depending on the standards in each country, but some important tests are applied in common. In this issue, we will examine the composition mixing ratio test.

This test tells you the ratio of the components of the well-mixed down using a standardized method. For example, if it is a duck down product of an 80/20 ratio, down should account for more than 80% of all the content contained in the product (Korean standard), and this can be verified via this test. This test is the most important of all the various tests as the ratio of down cluster in the down significantly affects the price as well as the warmness of the clothing.

Composition ratio inspection method

The order of the composition mixing ratio test is mainly in the order of ‘sample preparation → sampling → primary selection → secondary selection → results display’.

1. Sample preparation: A well-mixed sample is placed in a conditioning box to ensure a *constant weight.

* constant weight: In quantitative analysis, it refers to the weight of an object to be loaded already having reached a certain weight under certain conditions. Here, it refers to a state in which the mass is measured at an interval of one hour or more in the case of moisture balance, and 15 minutes or more in the case of oven drying. Constant weight means the difference before and after drying is 0.1% or less.

a. Moisture balance: The sample is preliminarily dried at a temperature of 40°C±5°C, then placed in the standard-state laboratory to reach the constant weight.

b. Oven drying: The sample is left in a dryer at 105°C±2°C to reach the constant weight.

2. Sampling: Two samples of 2g are collected from the upper, middle, and lower layers of the sample in the process described in 1.

3. Primary selection: 2g of the sample is classified into five components**, and the mass is precisely weighed to 0.1mg and the mass ratio is calculated.

** ① down / nestling down / down fiber and feather fiber ② waterfowl feathers ③ landfowl feathers ④ damaged feather ⑤ residues

4. Secondary selection: Among the primary selection components, ① down / nestling down / down fiber and feather fiber are mixed in a mixing box, and about 0.2g is collected from the upper / middle / lower layers. When the total amount is not 0.2g, the total amount is used as a secondary selection sample.

Down is classified into three kinds: down and nestling down / down fiber / feather fiber. The mass is precisely weighed to 0.1 mg, and the mass ratio of the first sample (2g) is calculated.

5. Results display: The average of the two test results shall be measured to the first decimal place and expressed as a percentage. The average value of the two test results shall be indicated.

Possibility of deviation of composition mixing rate test

Although the procedures and standards are clearly presented in the inspection manual, since the actual inspection is performed by humans, the criteria of sorting may vary somewhat for each inspector, and there is a possibility that the deviation may occur.

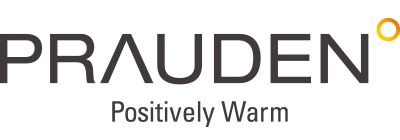

1. Damaged feathers: Can be classified as normal feathers depending on the degree of damage.

2. Nestling down: These are feathers/down in intermediate development, which can be classified as suitable feathers at the discretion of the inspector

3. Fiber: There are no clear criteria for the extent that fiber should be separated from down and feathers, so results may differ depending on the inspector.

1. Various types of damaged feathers / 2. Nestling down / 3. Fiber

If it is not an accredited testing laboratory or the inspectors are not skilled, deviations are likely to increase. Therefore, the inspection manual of IDFB (International Down and Feather Bureau), which is currently being used by many global brands, states that there may be a certain level of variation regarding the composition mixing ratio test as follows.

Down: ± 3% (± 5% if fiber accounts for more than 15%)

Feathers, Fiber: ± 3%

Waterfowl feathers, residues: ± 1 to 2%

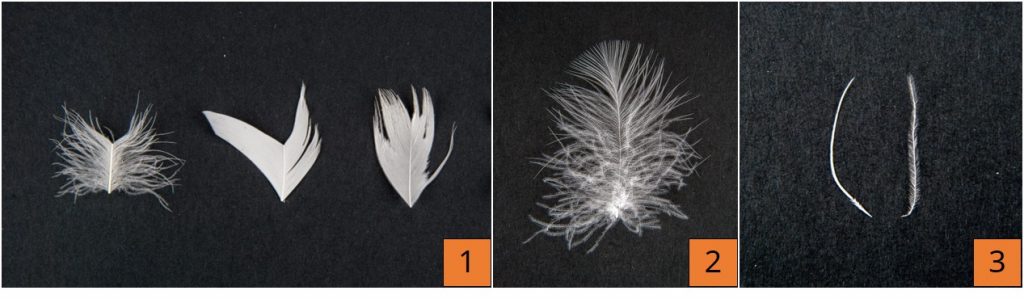

There is a little difference between the displayed allowable content adopted by each country and the actual amount, which reflects this situation. This is why you should check the content standards when purchasing a product.

<Comparison of Actual Content According to International Labeling Standards

<Comparison of Actual Content According to International Labeling Standards

(80%, Based on Finished Product)>

<Report on violation of content display>

Source: SBS News

The Smart Way to Buy Down

As mentioned above, different laboratories have different environments and inspectors have different degrees of proficiency. Therefore, there is an inevitable amount of deviation. Some companies even increase their margins by exploiting this deviation. So, in this situation, how do you wisely identify what to buy?

1. Before purchasing: Identify the test results of the independent testing institute.

2. After purchase (before sewing): Request a sample test of the received product to an external organization.

This is basic but very important. The main reason 2. is important is because it is very difficult to deal with out after sewing that the quality is less than stated. In this case, it is difficult to clarify who is responsible for the deficient quality, and for finished products that have already been produced, it can have heavy repercussions resulting in the brand’s image becoming tarnished. In the case of companies that do not have their own inspection centers or operate laboratories where expertise is poor due to insufficient know-how caused by not being in operation for a long time, they supply products with low quality that even they don’t know about, resulting in unexpectedly large amounts of poor quality products being distributed.

The Importance of Testing Laboratories

In order to reduce variations in quality, the IDFB has been working to maintain international inspection quality by operating the Certification System for Testing Laboratories from 2008. Verification can only be acquired after passing the test for two consecutive years as a result of analysis following inspection with the same received samples. A list of certified independent testing institutes can be found here.

Since 2016, the IDFB has extended this certification system to independent testing laboratories, and to corporate inspection offices. PRAUDEN acquired IDFB Recognition for Qualified Company Inspection Lab for the first time in Korea, securing the credibility of inspection quality. This certification means that the quality of the product is managed on an equal basis with the world’s accredited testing laboratories. More information about this certification can be found here.

As the price of down increases, the temptation to buy cheaper than the market price is growing, and the trend of purchasing low quality down only to later regret it is being repeated every year. The whole industry should maintain a discerning eye and try to use properly selected quality products so as not to cause distrust regarding all down products.

By PRAUDEN R&D Part, Oh Jun-jae