Warning! Counterfeit Glued Down!

2018-07-05

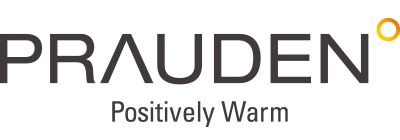

Down prices have risen sharply this year. Down prices in recent decades have been steadily declining since peaking in 2013, showing the lowest price in July 2016, but the price has risen steadily since the down demand has increased, showing a dramatic upward tick.

<Change in Raw Material Price>

First cause for this price hike is increased demand. In early 2017, when down prices stabilized, several global brands, who considered the prices tolerable, planned various down-style products. In addition, as demand continues to grow in China’s domestic market, down demand is increasing worldwide.

The second cause is the unstable supply from China. In China, which accounts for 80% of the supply, more stringent environmental regulations are being implemented. Unlike in the past, when the Chinese government allowed farms that did not meet environmental standards to be refurbished and resume operation, the Chinese government completely closed the farms and disposed of them so that they could not be restarted. Many poultry farms have been forced to shut down, resulting in a significant supplies bottleneck in down supply.

With demands going up to exceed supplies, the counterfeit down, which was relatively inexpensive for the apparel industry struggling to produce according to the margin of the already planned products, began to circulate. There are many problems in the industry due to the distribution of various types of counterfeit down. In this issue, we address the most serious problem, the ‘Glued Down (胶水绒)’.

The Truth of Glued Down

Glued down is a fake product that makes distinction from the authentic down with the naked eye difficult by attaching the impurities of the discard stage to a part of the down structure with adhesive. The production process is as follows.

1. Crush landfowl feathers(chicken) or waterfowl feathers(duck, goose). Among them, soft feather fibers are classified and prepared. Let’s call this “material A”.

2. Wash and process the natural down so that the down content is above 88%. Let’s call this “material B”.

3. Mix materials A and B uniformly at a ratio of 5: 5. When mixed, the down content is between 44 and 51%. Let’s call this “material C”.

4. Material C is cleaned in the same process as the general down-production process. Thereafter, the water level is adjusted to a low level, and an adhesive corresponding to 10% of the weight of the charged material C is added and mixed for 20 minutes. Leave it for 30 minutes, then dehydrate and dry the mixture. In this process, the feather fiber (material A) is entangled with the adhesive on the down cluster (material B) and completes the glued down. The down content increases from 44 ~ 51% to over 88%.

* Adhesive can be directly sprayed on material C to attach fibers.

Source: China Down Industry Association (中国羽绒工业协会)

Problems Using Glued Down

1. Worsened Insulation and Resilience: Thermal insulation and restorative power, which is the core function of down, is determined by the structure and elasticity of the down cluster. The fibers of the down cluster are not intertwined with each other, but they repel and swell up, and the air is kept light and warm. It is excellent in resilience. It can be stored in a folded state for several months after the winter season, and revert back perfectly in its original shape when taken out. However, what looks like the down cluster of the glued down is actually a bundle of feather fibers, or they are clinging to the down cluster. The former is only a lump without any function, and the latter causes the function of the natural down cluster to deteriorate.

2. Clear Defect in Product Appearance: Adhesives used for making glued down are not strong kinds like adhesives for woodwork, so feather fibers are easily separated even when a handful of glued down cluster is pulled a little. Due to friction during wearing or washing, the separated feather fibers will escape through the strands. Not only does it become a cause for customer complaint due to continuous feather loss, this can cause the loss of bulk and flatten the appearance of the product.

3. Hazardous Ingredient Risk: The safety of the material used for adhesion cannot be verified, which could lead to secondary damage due to harmful components.

4. Quality Standard Violation: In most countries, feather fibers, which are included in high quality natural down, are defined at levels below 10%, which is determined through long research to maintain down quality. However, the glued down is a temporary fixation of the feather fibers in amounts which far exceed the specified levels with adhesive, which obviously violates the quality standard.

As a result, consumers are directly affected by counterfeit glued down products, and brands that sell these low-priced products are not only liable to compensate consumers, but there will also be a devastating impact on the brand image they have accumulated over the years.

Distribution Method of Glued Down

Glued down is distributed by itself, and it is also distributed mixed with natural down. When selling the glued down mixed with natural down, the content of glued down may be high or low, increasing confusion in the part of buyers.

How to Distinguish Glued Down

Glued down is difficult to distinguish easily by the naked eye. One can see the difference in the above photos because the glued down is photographed on its own, but glued down is actually mixed with natural down at various ratios. It is recommended that the following method of discrimination be used only as a reference, and use quality testing by the professional institution as standard.

1. Check for Static Electricity: Down mixed with glued down will stick to sample bag or test tool due to static electricity unlike natural down during sample collection or testing.

A. Glued down sticking to poly bag

A. Glued down sticking to poly bag

B. Glued down sticking to wooden rod for fill power test

C. Glued down sticking inside cylinder for fill power test

Image Source: China Down Gold Network

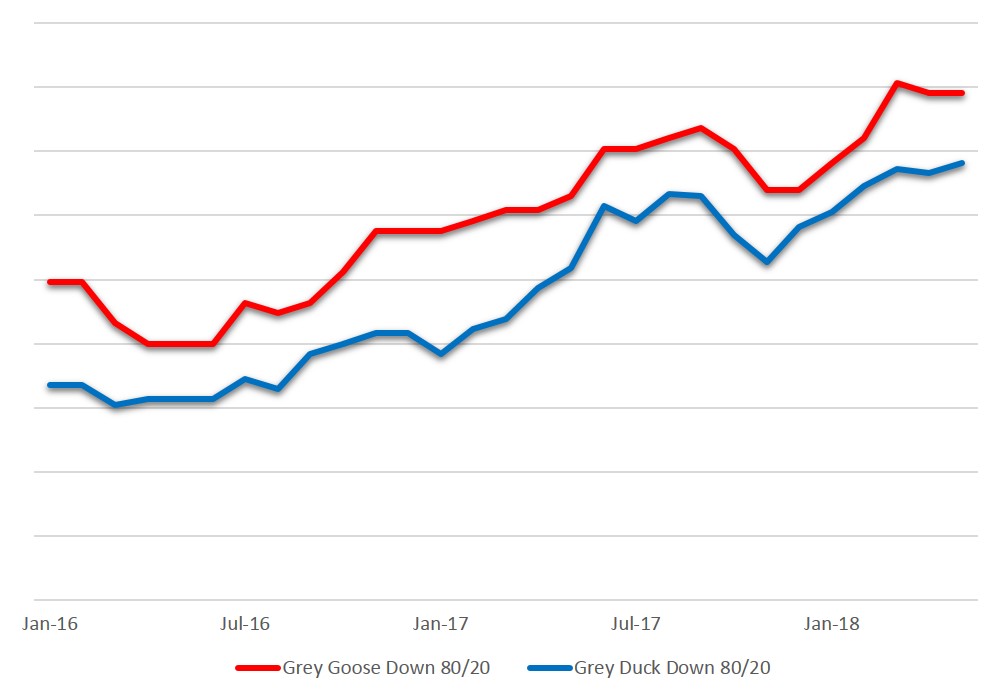

2. Microscopy Confirmation: When observed under an electron microscope, a lump of glue that was not visible to the naked eye was observed between the down cluster fibers.

<Glued Down, seen in Electron Microscope. One can see adhesive lump inside red circles>

Image Source: 2018 IDFL Down Seminar

How to Buy Products while not being fooled by Glued Downs?

With the increased demand and unstable supply, the rising price is a natural trend in terms of supply and demand. One has to be careful of some malicious sellers who call this situation as selfish behavior in the industry, make the buyer suspect, and use it to mislead buyers at relatively low prices. This phenomenon becomes worse when the down price goes up like now.

The easiest and fastest way to minimize the risk of quality risk and future loss is to select a supplier that has a considerable expertise and is well-qualified for the company’s operations and quality control, rather than numbers on a product quote. However, if you have a diverse set of cooperative partner chains for a variety of reasons, we recommend that you conduct extensive and thorough testing of candidates.

1. Company Verification: Be sure to check the source of raw materials and the actual production site as well as basic information such as performance and report.

2. Post-purchase Inspection: Send a sufficient amount of samples to a professional down testing laboratory or to a research laboratory that has obtained international certification for down testing. If there are multiple LOTs, go through all the quality tests for each LOT.

By PRAUDEN Sourcing Part, Lee Mi Ra