PRAUDEN Installs New Climate Controlled Conditioning Room

2017-08-03

Fill power is one of the most crucial factors among many others that determine the quality of down. Down with higher fill power has better quality than others possessing the same content and weight, which means that fill power also affects the overall price of down. As a factor that determines the quality of down, the measurement of fill power is greatly influenced by the external environment due to the nature of the material. Therefore, it is very important to precisely check the fill power to produce down products of desired quality.

PRAUDEN has newly installed a new climate controlled conditioning room for the measurement of fill power as a means to supply down with accurately assessed quality. Since the climate controlled conditioning room is not affected by the external environment, it can maintain the temperature and humidity that meet fill power measurement standards. In other words, it allows for precise fill power measurement by ensuring optimal conditions.

What is fill power?

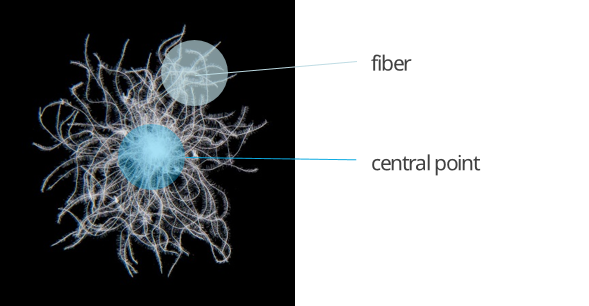

The soft and dense down cluster on the chest area of waterfowl is called down. It is composed of individual fibers that are connected to a central point and extend in every direction. Down traps in warm air between these fibers, and thus provides a thermal insulation effect. As fibers are not tangled but resilient to each other, they allow for down to keep inflating. This nature of down is called resilience or bulkiness. The higher the bulkiness is, more air is trapped in down for warmth, exhibiting the high quality.

Fill Power is an index representing the bulkiness of down and a unit for measuring the force that a certain amount of down has to withstand standardized pressure. Generally, 600 FP or higher is considered to be good quality, and 800 FP or higher is considered to be premium quality.

<The structure of down>

Measurement Standards for Fill Power

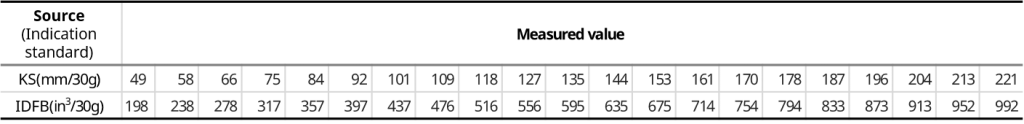

Fill power testing method and measurement unit differ according to country. In general, the International Down & Feather Bureau (IDFB)’s test method and indications standard (in3/30g), which are applicable all over the world, are used. Currently, Korea uses both the unit of height (mm/30g) and unit of volume (cm3/30g).

<Contrast Table between KS’s Fill Height and IDFB’s Fill Volume>

Reference: IDFL – FILL POWER CONVERSION TABLES

Correlation between Fill Power and Temperature & Humidity

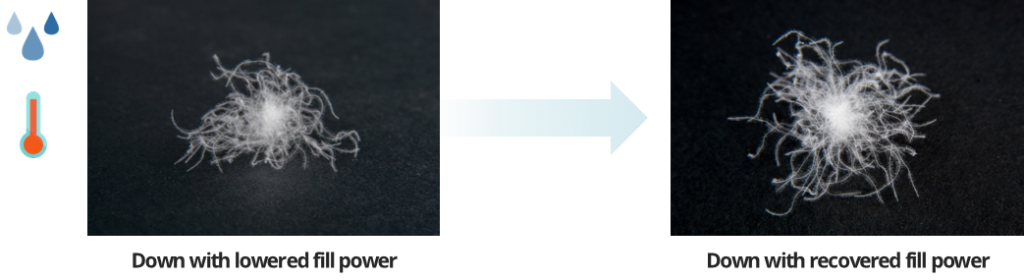

Various factors influence the results of fill power testing. Fill power values vary depending on the compression state of the samples, the temperature and humidity of the laboratory, the conditioning time of the samples for the measurement, the order and method of the testing, and the state of the testing tools. In particular, down which is composed of natural molecules such as proteins and amino acids exhibits changes in its state depending on the external temperature and humidity. Therefore, thorough temperature and humidity control are essential for accurate fill power measurement.

As temperature and humidity increase, down & feather tend to trap more moisture in the air. As a result, the fibers of down become heavier and droop while less static electricity is generated, resulting in a lower measured value of fill power than the true value. It is the same principle as with hair drooping down on a rainy day.

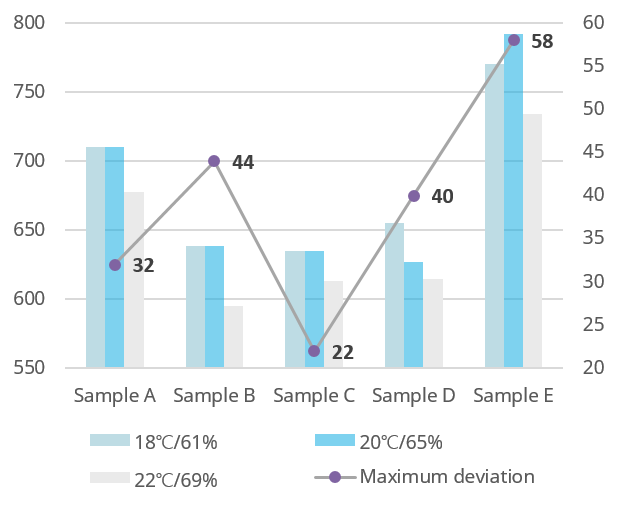

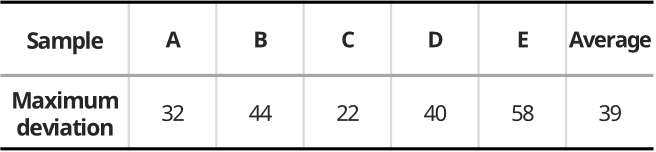

According to the IDFB’s conditioning requirements, the temperature should be constant between 20±2°C, and relative humidity between 65±4% for 48 to 72 hours. As seen in the chart below, due to the nature of down that is sensitive to the surrounding environment, even testing conducted in conditions meeting the proper requirements can lead to large deviations. Differences in measured values become greater as differences between temperature and humidity increase. Since fill power is a key factor for differences in the value of down, it is important to check true fill power values by conducting testing in a constant environment.

<Fill Power Measured Values according to Temperature and Humidity Changes

within the IDFB Conditioning Requirements>

< Fill Power Measurement Deviations according to Temperature and Humidity Changes

within the IDFB Conditioning Requirements>

PRAUDEN’s New Climate Controlled Conditioning Room

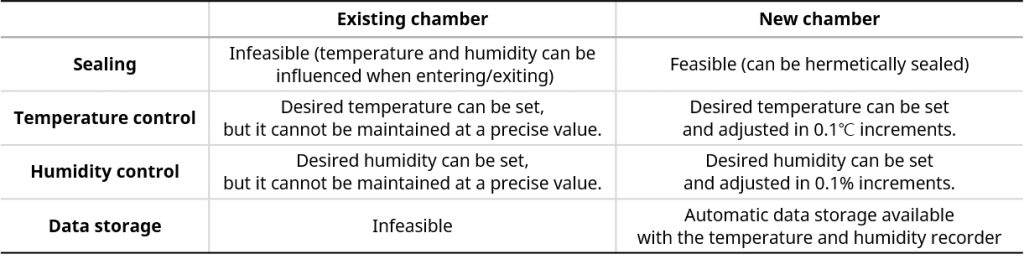

PRAUDEN’s new climate controlled conditioning room is a space dedicated for fill power measurement, which circulates air set at a certain temperature and humidity in a sealed space to create and maintain a precise environment. The temperature and humidity are in accordance with the International Down & Feather Bureau (IDFB)’s standards.

<Existing(Left) and New(Right) Climate Controlled Conditioning Rooms>

<Enhancement for the New Climate Controlled Conditioning Room>

This new climate controlled conditioning room that enables accurate measurement of the true fill power of down & feathers without being influenced by the external environment has been completed in the Cheonan Plant and will be expanded to NPA (China) and VINA PRAUDEN (Vietnam) in the future. Soon, you will be able to experience PRAUDEN down of the same quality standards as upheld in products of any corporation.

By PRAUDEN Brand Part, Lee Su-kyung