How to Spot Glued Down?

2019-12-26

Glued down is now on the horizon again since the price of raw materials has been rising over the past three years and the trend never seems to subside soon. For more information of glued down and how to avoid buying them, see one of our past articles here.

IDFB’s New Testing Regulations to Spot Glued Down

Even industry’s professionals are hard to tell glued down since these are not like the past and now seem ‘perfectly real’ as it looks contrary to the past years. The industry’s efforts to counter those fake to secure reliability and protect customers has led IDFB (International Down and Feather Bureau) to update the IDFB Testing Regulations to add some sophisticated methodologies to spot glued down. An internationally recognized test method developer for down and feather, IDFB has developed the Testing Regulations, each edition of which has been internationally recognized as the standard down and feather inspection. The up-to-date IDFB Testing Regulations present a couple of glued down spotting methods – Part 20-A and Part 20-B – as follows:

Part 20-A Glued Down Evaluation (CFDIA Comprehensive Method)

Part 20-A mimics the method presents in the CFDIA Technology Standard issued last May by CFDIA (China Feather and Down Industrial Association).

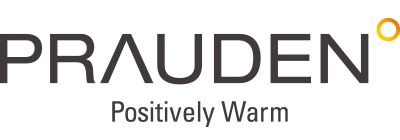

1. Visual Inspection

Inappropriate distribution of compositions, poor structural definition and existence of ‘cocooned’ down defines glued down:

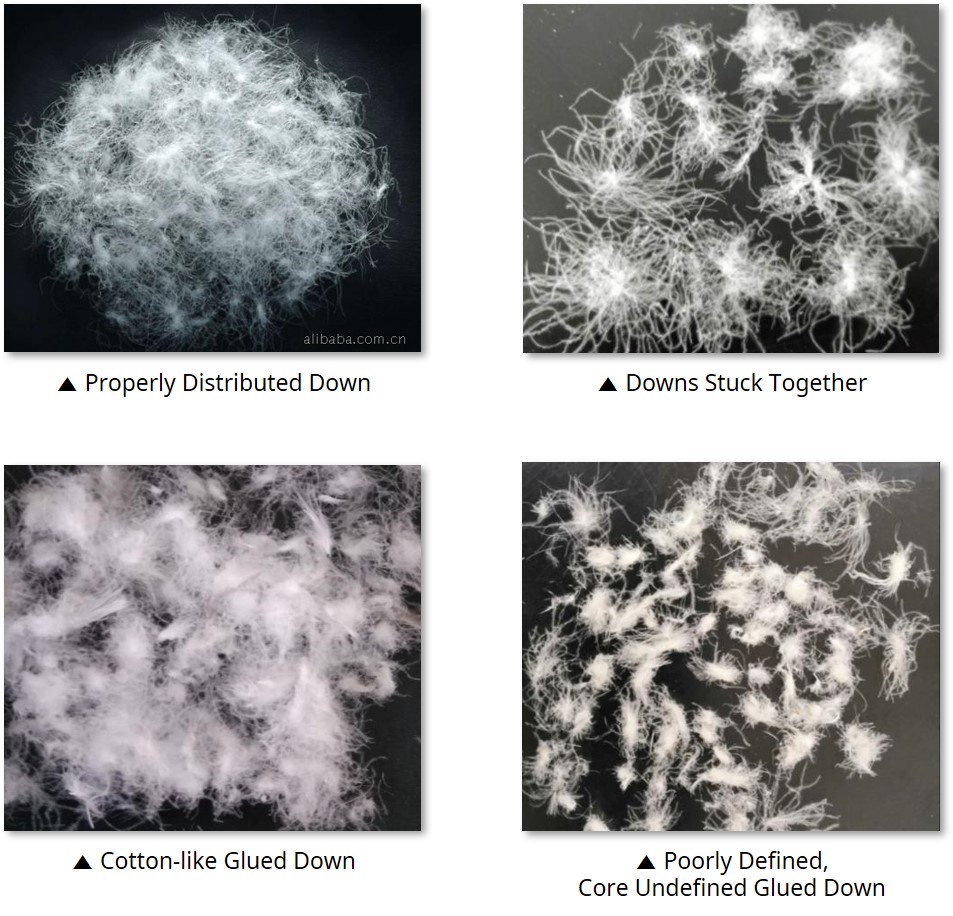

2. Microscopic Inspection

2. Microscopic Inspection

Inspection is performed by using a 100+x microscope to spot suspected down to detect ‘cocooned’ elements and excessive fibers.

3. Physico-chemical Inspection

3. Physico-chemical Inspection

Both infrared spectrum method and fluorescent X-rays are used to detect improper chemical elements and chemical substances.

Down is deemed glued if:

– Under either visual inspection or microscopic inspection, more than 10 ‘cocooned’ elements are detected; or

– Glued down is detected in at least two of any inspections above (visual, microscopic, physic-chemical).

Part 20-B Glue Down Evaluation (Visual and Microfiche Method)

1. Visual and Haptic Inspection

Improperly distributed or ‘cocooned’ elements are visually and haptically inspected, paying particular attention to the shape of fibers and existence of alien substances.

2. Content Analysis

A two-step content analysis applies; ‘cocooned’ down, feathers and fibers are spotted first, followed by analyzing volume of fibers, damaged feathers and dusts when a down is shaken suspended.

3. Microfiching

A 70+x microfiche – a film-like inspection medium – is used to detect dark spots or ring-like fragments.

Results for inspection are as follows:

– Suspected glued down (content of glued down exceeds 50%)

– Evidenced glued down (content of glued down is between 10 and 49%)

– Glued down not suspected (content of glued down less than 10%)

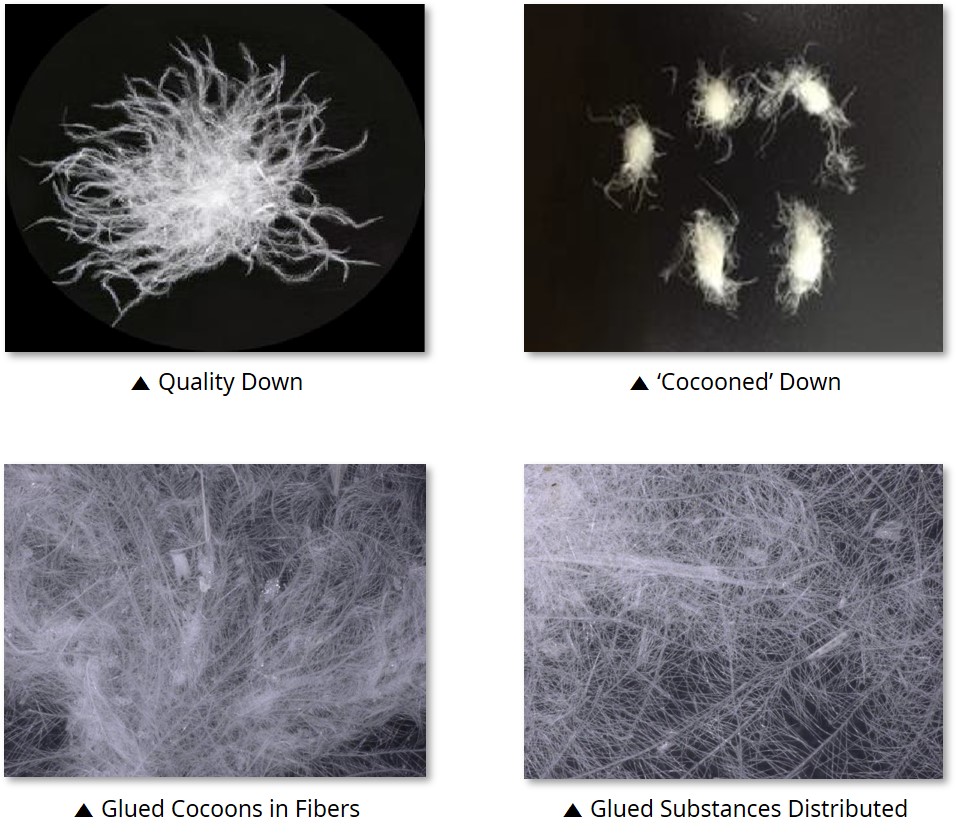

<Regular Down (Left) and Glued Down (Right)>

Source: IDFB

How to Utilize Up-to-date Glued Down Inspection Methods?

While the conventional work process mandates quality assurance submitted by the supplier, the suppliers may now inspect the down on its own using the globally recognized glued down inspection methods to subside growing concerns on glued down.

Not all down needs to be subject to the glued down inspection. It is highly recommended, however, to perform glued down inspection in case:

– Sourcing from a new buyer; or

– Sourcing cheap down.

It is expected, the reliable glued down inspection methods and keeping the methods up to date weed the glued down suppliers out of the market sooner or later.

By Lee Mi-ra, Sourcing Part, PRAUDEN