Down Quality Determining Factor 2. Fill Power

2018-07-05

PRAUDEN features articles that introduce important factors that determine the quality of the down so that consumers can make informed purchases. Following the ‘content’ of the last issue, we will look at the ‘fill power’ in this issue.

Down Quality Determining Factor 1. Content

What is “Fill Power?”

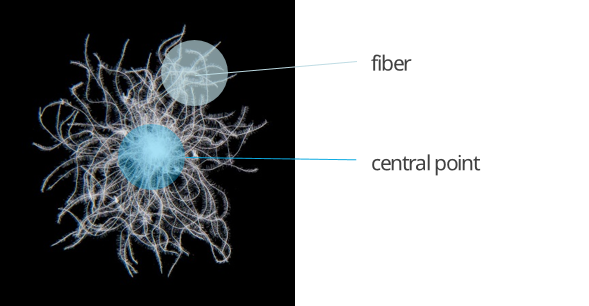

To know what fill power is, one first needs to understand the structure of the down. The soft and dense down cluster on the chest area of waterfowl is called down. It is composed of individual fibers that are connected to a central point and extend in every direction. Down traps in warm air between these fibers, and thus provides a thermal insulation effect.

<The structure of down cluster>

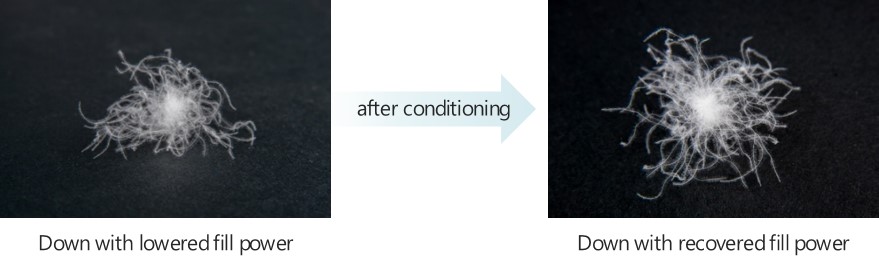

As fibers are not tangled but resilient to each other, they allow for down to keep inflating. This nature of down is called resilience or bulkiness. The higher the bulkiness is, more air is trapped in down for warmth, exhibiting the high quality.

Fill Power is an index representing the bulkiness of down and a unit for measuring the force that a certain amount of down has to withstand standardized pressure. Generally, 600 FP or higher is considered to be good quality, and 800 FP or higher is considered to be premium quality.

Why is Fill Power Important?

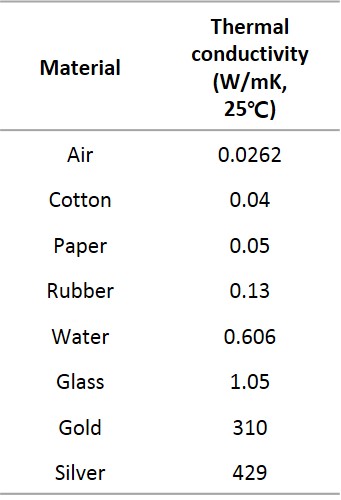

There are many kinds of filling materials for keeping warm such as wool, polyester, etc., but the principle is the same. Said materials create an air layer inside the filler, minimize the heat loss to the outside, and shut out the cold air outside. The thermal conductivity of air is very low compared to other materials.

<Relative Thermal Conductivity Comparison of Substances>

Source: The Engineering ToolBox

Down is warmer than other fillers because it contains more air at the same weight. A high degree of fill power means that the fiber’s repulsive force is high so that it can contain a lot of air between the fibers. As a result, the higher the fill power, the higher the warmth, and the inherent performance that makes down stand out from other fillers is made even more exceptional.

How to Check the Fill Power

The fill power test is comprised of ‘Conditioning → Testing → Display Results’.

Conditioning refers to the process that equalizes any conditions that may affect the test results so that the fill power can be measured objectively before it is tested. Down which is composed of natural molecules such as proteins and amino acids exhibits changes in its state depending on the external temperature and humidity. Therefore, thorough temperature and humidity control are essential for accurate fill power measurement. Because the test results can vary greatly depending on the conditioning, this stage is essential to the test.

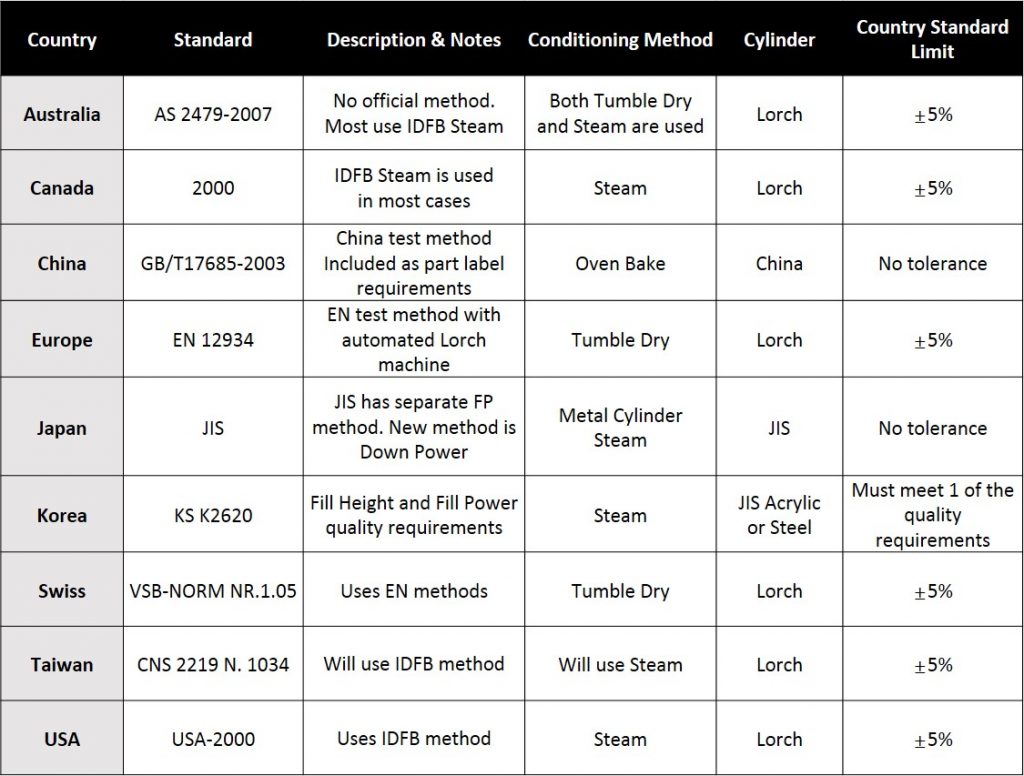

There are various types of conditioning methods and they are applied differently in different countries. Here, we describe the ‘Steam Conditioning method’ is used in many countries such as USA, Japan, and recommended by IDFL because of consistency of inspection.

<Note: Each country’s fill power measurement standard>

Source: IDFL

1. Conditioning

1) Put 35g (± 2g) of sample in the conditioning box and relax the clumped or matted part with wooden rod.

2) Spray for 80 seconds to wet the sample using a steamer.

3) Wait for 5 (± 2) minutes.

4) Use the hair dryer to completely dry the sample for at least 2 minutes.

5) If the inside of the conditioning box is wet, dry it together.

6) Store the conditioning box in a climate controlled conditioning room for 48 ~ 72 hours and conduct the test. The temperature of the climate controlled conditioning room is maintained at 20 ± 2°C and the relative humidity at 65 ± 4% (according to the international standard ISO139).

2. Testing

1) In order to remove static, wash the measuring cylinder a minimum of once per day, and at least once after every 30 individual measurements.

2) Fill about 30 g of the conditioned sample in a measuring container. Do not compress or touch the sample.

3) Loosen the sample contained in the cylinder with wooden rods.

4) Slowly drop the manual plate to measure the height.

5) Repeat the loosening and measuring of the two samples, repeating three times respectively.

<Dropping the manual plate in cylinder>

3. Display Results

The average of the results of three measurements of each sample is expressed as an integer (total of six measurements).

Countries have differing fill power testing method and measurement unit. In general, we use the International Down & Feather Bureau (IDFB) test method and marking standard (in³ / 30g) which can be used all over the world. In Korea, both the unit of height (㎜ / 30g) and the unit of volume (㎝³ / 30g) are used. The test criteria can be found in here.

Probability of Fill Power Test Variation

Although the procedures and standards are clearly presented in the test manual, since the actual test is carried out by a person, there is a possibility that variations in the detailed method of operation may occur between the testers.

1. Steam Injection and Drying Method: The time for spraying and drying steam on the sample is specified as the minimum standard, and depending on the situation, the sample can be processed for a longer time, and the state of the sample may be changed accordingly.

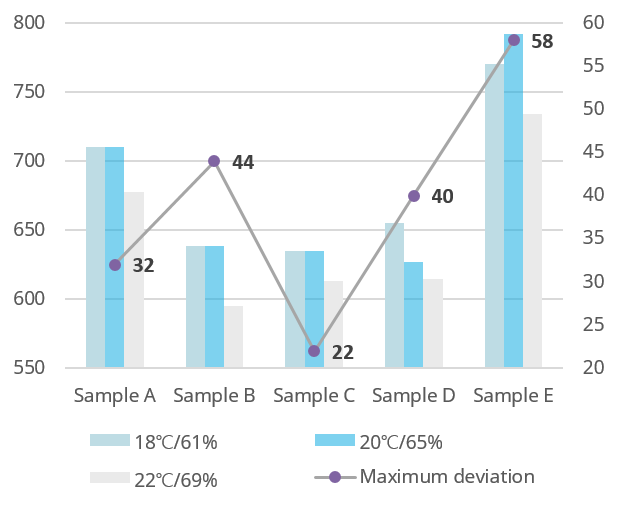

2. Condition of Climate Controlled Conditioning Room: According to the IDFB’s conditioning regulations, the temperature should be constant between 20 ± 2 ° C and 65 ± 4% for 48 to 72 hours. As can be seen in the chart below, even if the test is conducted within the specification, a large deviation may occur since down is sensitive to the surrounding environment. The difference between these measured values becomes larger as the difference between temperature and humidity is increased. It is very difficult to establish and maintain a constant condition in a climate controlled conditioning room that is not properly sealed and therefore susceptible to outside environment.

<Fill Power Measured Values and Tolerances according to Temperature and Humidity Changes

within the IDFB Conditioning Requirements>

3. Sample Relaxation Method: There are no detailed rules in the manual, leading to potential deviations.

The possibility of such deviations can only be increased if uncertified testing laboratories or unskilled inspectors are involved. As a testament to this, the IDFB’s inspection manual, which is currently being used by many global brands, states that there may be a deviation of up to ± 5% with respect to the fill power test.

A Smart Way to Buy Down

Down is a natural by-product, not an artificially created material, and is sensitive to the external environment. Especially, among the down quality testing, the fill power is the item which is most affected by the outside environment. It is most important to accurately measure the fill power down itself, free from temporary influences due to the external environment. How can we confirm this?

1. Understand the diversity of conditioning and inspection methods and evaluate the product on a consistent basis. It is advisable to use the most internationally accepted standards possible. We recommend the IDFB’s steam conditioning method.

2. The inspection is commissioned to a reliable institution considering the history of the institution, the proficiency of the inspector, the inspection facility and the environment.

3. Use down from a company with a proven track record.

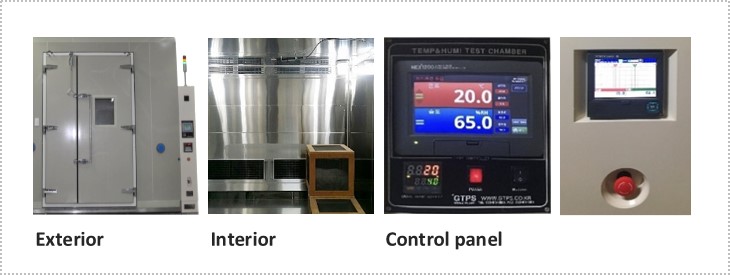

PRAUDEN’s Electronic Climate Controlled Conditioning Room

PRAUDEN recognized the importance of conditioning from early on, and in 2017 it introduced the electronic climate controlled conditioning room for the first time in Korea. It is a space dedicated for fill power measurement, which circulates air set at a certain temperature and humidity in a sealed space to create and maintain a precise environment. The temperature and humidity are in accordance with the International Down & Feather Bureau (IDFB)’s standards.

<PRAUDEN’s Electronic Climate Controlled Conditioning Room >

<PRAUDEN’s Electronic Climate Controlled Conditioning Room >

Through this, PRAUDEN minimizes deviation of fill power test and improves accuracy. This is amply proven with the “IDFB Recognition of Qualified Company Inspection Lab”, first acquired in Korea by PRAUDEN in this January. An IDFB Qualified Company Inspection Lab is able to correctly perform all IDFB testing, taking advantage of the technologies required for a Qualified Testing Institute. More information about this can be found here.

Price fluctuations are continuing following the unstable down supply situation. It is safe to buy reliable quality products through qualified down suppliers. We hope that transparent, industry-wide transactions will be made with wise judgments based on accurate information.

By PRAUDEN R & D Part, Oh Joon Jae