Synthetic Insulation Production Process: Part 3. Recycling

2020-11-30

The last two articles focused on how petroleum turns to synthetic insulation. This article will guide you to the production process of recycled polyester insulation, an essential material for sustainable fashion.

Synthetic Insulation Production Process: Part 1. Raw materials

Synthetic Insulation Production Process: Part 2. Processing

What is recycled polyester insulation?

Unlike virgin polyester directly produced from petroleum, recycled polyester is made from post-consumer polyethylene terephthalate (PET) bottles, most commonly water bottles. PET bottles are melted to produce yarn, from which recycled polyester insulation is made. An average-size jacket for adults made from recycled polyester would mean ten 500㎖ PET bottles recycled.

What are the benefits of recycled polyester?

Using recycled polyester helps reduce reliance on petroleum for raw materials and prevent PET bottles from being landfilled, hence less impact on the soil, air, and water. More than 30% savings on resources such as water and electricity than virgin polyester are another environmentally-friendly advantage.

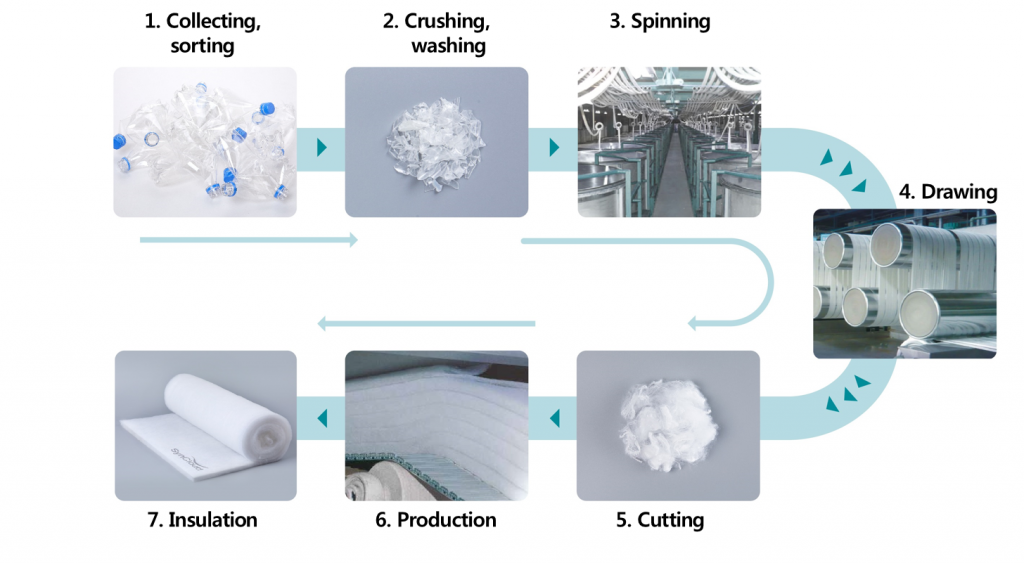

How is recycled polyester insulation made?

1. Collecting

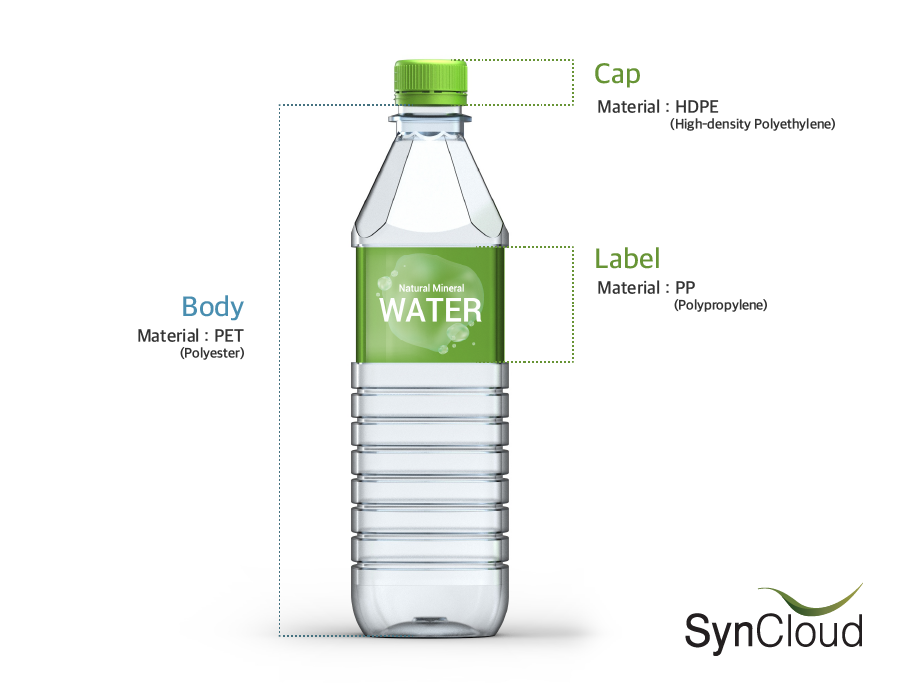

Post-consumer PET bottles are collected by recyclables collection services. A PET bottle is composed of a body (PET), a cap (HDPE), and a label (PP). Among them, the PET body is recycled.

The first step is to remove foreign bodies and labels from the PET bottles. Residual labels and adhesives contribute to yarn being choppy and breaking easily. Bottle caps are made from HDPE, which is processed separately.

<Composition of the PET bottle and materials used>

2. Sorting

The PET bottle bodies are further sorted out to separate clear bottles from colored ones. Clear PET bottles are easier to process and of the highest quality. The yarn for the insulation is made from these colorless PET bottles. Colored PET bottles are used to make other plastic products, furniture, or industrial wadding.

3. Crushing

Once sorted, the PET bottles are compressed and crushed to make flakes. Smaller in size with wide surface areas, they can be easily processed to shape into other forms.

4. Washing

The flakes are washed to remove debris one last time.

<Flakes after washing>

The process afterwards is the same as that of virgin polyester.

Synthetic Insulation Production Process: Part 2. Processing

<Recycled polyester production process>

<From a PET bottle to recycled insulation>

<Gap – Cold Control Puffer Bomber Jacket,

used SynCloud’s recycled insulation>

Image source: eBay

SynCloud’s technology and strictly managed process ensure that only clear plastic bottles are used to achieve excellent uniformity and clarity in color. Compared to colored materials, transparent bottles are easier to process and offer greater resilience. Currently Pan-Pacific uses recycled polyester in more than 85% of its SynCloud products and plans to further promote its use.

By Park Kyung-jun, SynCloud Part