Future of the Down Industry, Recycled Down

2019-08-21

The perception of sustainability, a global issue, can change the value or structure of an industry. Recycling down is drawing attention in terms of sustainability, which minimizes the environmental impact of resource reuse. The demand for recycled down is also increasing, led by global brands seeking sustainability, such as Patagonia and Nau.

What is Recycled Down?

Recycled down is down that has been collected from discarded products after customer use, which is then processed and reused. If the down hasn’t gone through the end consumer stage, such as collecting and using leftover feathers from the production process, it is not a true recycled down. The former is called pre-consumer down and the latter is called post-consumer down, and this deals only with down recycled after use by consumers.

*Down whose concept is the opposite of recycled down is called “virgin down.”

Change in Meaning of Recycled Down

In the past, reusing down was thought of negatively. In order to reduce the unit price of virgin down production, used down was mixed with virgin down. Because of this, in Europe, where the down industry was developed early, labeling standards include whether the virgin down is new or not.

Reusing down is now thought of positively in terms of sustainability.

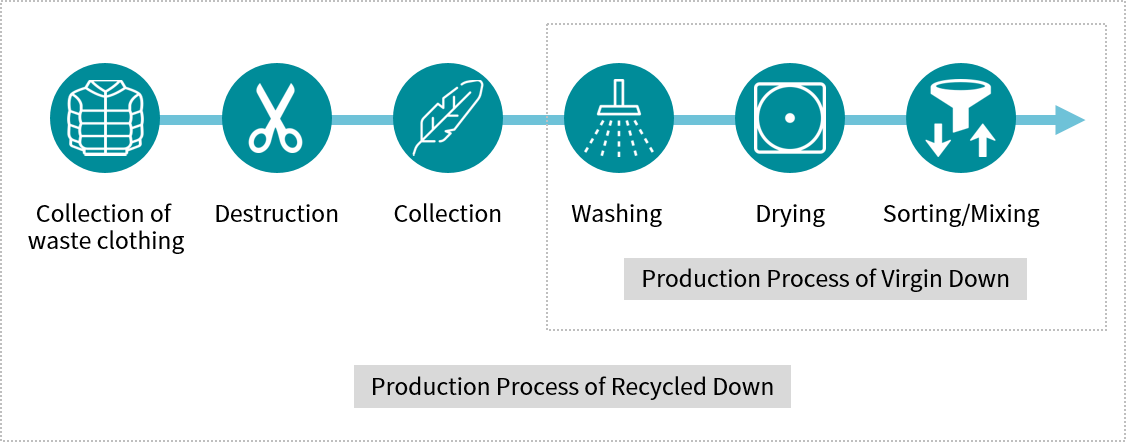

Production Process of Recycled Down

The production process of recycled down is basically the same as the process of producing virgin down, except at the raw material collection stage.

Used goods (clothing, bedding, etc.) are collected after use. The outer surface of the waste product is cut to collect down by color and it is stored in a ventilated bag. The collected down contains foreign substances, contaminated parts, scraped or damaged feathers and dust generated during use, and cannot be used right away. Only the parts that can be removed and provide warmth should be selected. This process is identical to the production process of virgin down. Down is cleaned using eco-friendly detergent to remove contaminants and is sterilized and dried at high temperatures while controlling its oil components. After cooling, a separator and mixer are used to finalize the required specifications.

Quality of Recycled Down

Recycled down produced through the proper processes is not much different in terms of overall function compared to the quality of virgin down which has similar fill power.

The recycled down quality-checking method is the same as that of virgin down. (Go here to learn about testing down quality.) It is possible to test fill power, content, black points, oil and fat, and others. However, since both duck down and goose down are mixed during the collection process, the species identification test to distinguish them is not meaningful.

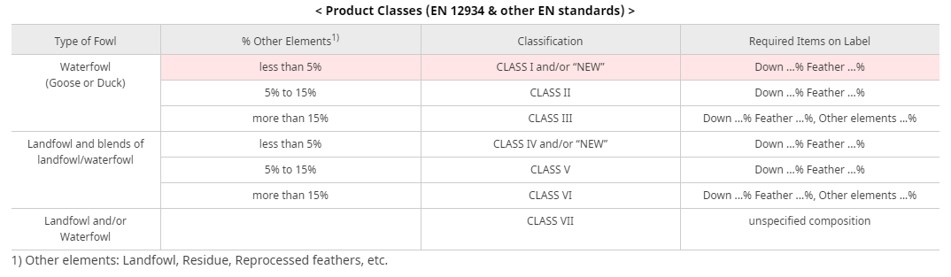

Labeling Standards of Recycled Down

Currently, it is possible to label the type and content of fillers on the care label applying the virgin down labeling standards. However, since recycled down is not an element included on the care label, it is recommended to use a separate marketing element such as hangtag or website to provide customers with guidance.

Most current down quality labeling standards are applied to new products, not recycled products, and there are no recycled down labeling standards as of yet. However, as the distribution volume is expected to increase in the future, in-depth discussions should be made on whether it would be appropriate to apply the existing labeling criteria for recycled down.

Advantages of Recycled Down

Recycled down is a good alternative to dealing with unstable down prices in business as well as in the social context of pursuing sustainability. If down production decreases due to natural disasters, epidemics, or national regulations, prices and supplies will fluctuate, and recycled down will be somewhat free of such fluctuations.

Precautions for Purchasing Recycled Down

1. Quality: Since recycled down is produced by collecting and mixing products of various standards, the larger order quantities are, the more difficult it will be to guarantee uniformity of quality across the entire quantity. Therefore, producers with proven testing technology and production-related know-how are selected to ensure uniform and stable quality for the entire quantity ordered.

2. Transparency: The entire process must be transparent, including whether the raw material is actually collected from the discarded goods of consumers and whether it has not been mixed with other raw materials in the production process. For this purpose, it is recommended to check international recycling certifications such as RCS and GRS.

<Certification logos of RCS(left) and GRS(right)>

3. Pricing: A great deal of manpower is required to collect waste clothing and to collect only down from this and commercialize it after processing. In addition, the price gap with virgin down is not large because supply and demand is not stable. If the price is unusually low, it is likely to be unwashed, and care and processing have not been performed properly.

PRAUDEN’s Effort

PRAUDEN has established a reliable domestic and international raw material collection system in order to stably supply high-quality recycled down. Recycled Claim Standard (RCS) certification and the Global Recycle Standard (GRS) certification are international textile certifications for recycling. For the first time in Korea down industry, we have acquired both certifications for recycled polyester item and are also awaiting imminent arrival of GRS certification for recycled down item.

Please contact us at down@prauden.co.kr for more information on purchasing recycled down or disposal of bulk down products.

By Lee Mi-ra, Sourcing Part, PRAUDEN