New conceptual odorless down, TopDeo

2017-06-09

Down, the warmest and lightest material among natural materials, has numerous advantages that cannot be replaced with chemical fillings. With outstanding air permeability, down absorbs and emits heat and moisture by expanding or shrinking depending on the temperature and humidity in order to maintain a constant temperature. Down clusters which are not tangled but resilient to each other are easily recovered to their original state when unfolded after being pressed. In addition, down requires little energy for production and is an eco-friendly material manufactured as a by-product of the food industry.

As down is a natural material, it has a drawback. The odor. Down is mainly made of keratin, a family of fibrous structural proteins, and has similar ingredients as hair and wool. Protein-based materials may emit a smell when the humidity level is high. Finished down products such as down jackets are generally produced during summer in nations with an advanced sewing industry such as Vietnam, Indonesia, and Myanmar. If moist down is packed in polythene bags and put into boxes, it may emit a peculiar odor of proteins. It is a natural characteristic of proteins. Although the odor may be reduced after drying, some customers consider the smell as a defect and complain.

PRAUDEN launched new conceptual odorless down, “TopDeo Coated Down” to overcome the disadvantages while keeping the advantages.

PRAUDEN’s special processing for removing odors

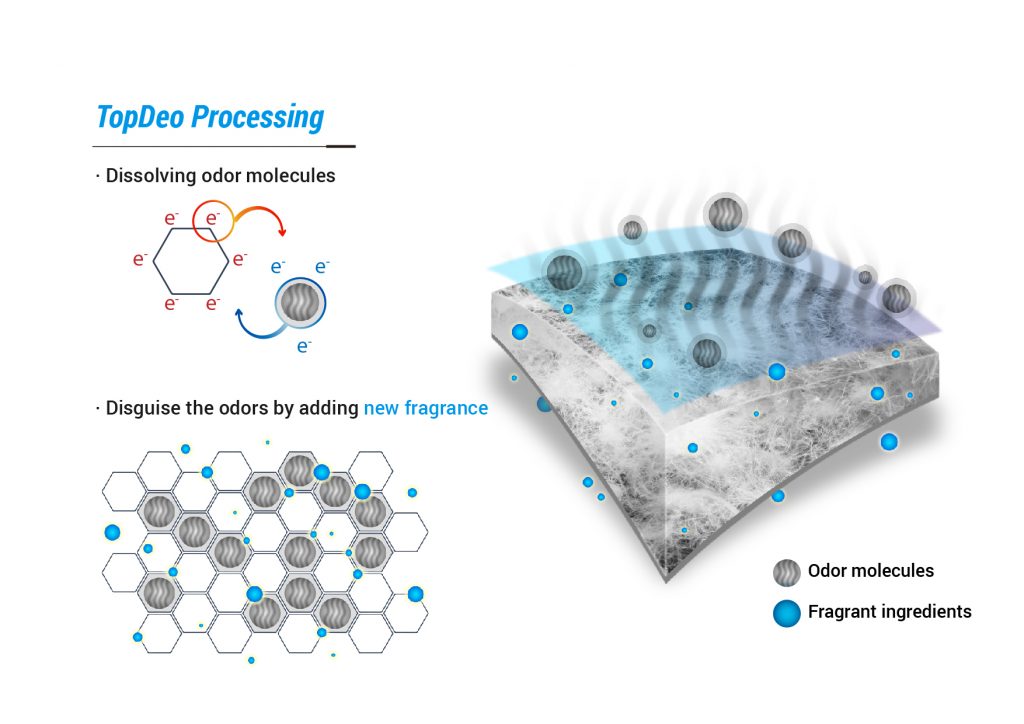

The mechanism of the special processing for TopDeo is as shown below.

1. Breaking up molecules causing the odor through chemical reactions

2. Trapping the molecules inside compounds of a pore structure

3. Covering the odor with the fragrances of the specially processed solution

<Mechanism of TopDeo special processing>

Some odor-causing molecules in proteins stimulate our olfactory senses and we smell the odors. We can remove the odors by getting rid of the causative molecules or changing their structures. PRAUDEN’s TopDeo special processing extinguishes the odors fundamentally based on this mechanism.

Scented down on the market is made by spraying fragrant ingredients on down to hide its particular smell. If such down products are used for a long period of time or washed repetitively, the fragrant ingredients may disappear and the odors may come back. PRAUDEN’s TopDeo special processing which fundamentally removes the causes of the smell has no such issue. This processing technology developed for the first time in Korea has been applied for a patent.

Harmless processing techniques

The processing solution of TopDeo is made of general ingredients widely used for deodorants and sunscreens. Its safety and harmlessness have been proven.

More precise analysis techniques

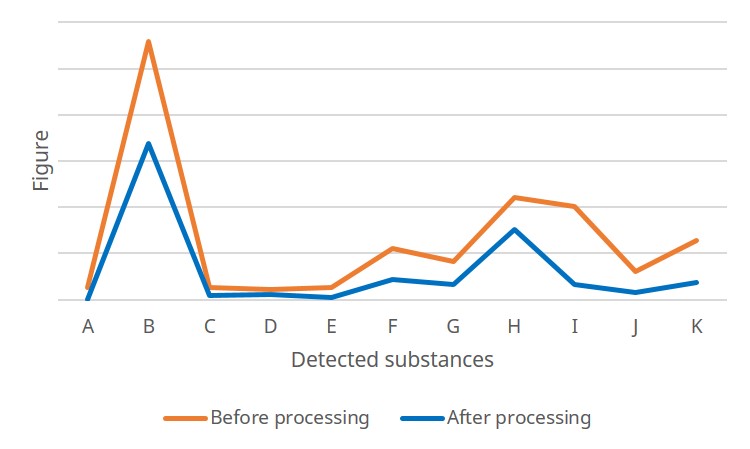

Generally a sensory analysis is used for a smell test. Human testers assess levels of smell by intuition. PRAUDEN introduced the following analysis techniques for more professional, objective, and reliable test results.

1. Instrumental analysis: Use a measuring instrument to analyze odors and compare the levels of smell before and after the process.

<Measurement results before and after the process>

<Measurement results before and after the process>

2. Odor contribution analysis: Analyze the contribution rate of each ingredient and numerically measure the levels of smell before and after the process.

This analysis technique is widely used by the automobile industry of Korea. PRAUDEN guarantees pleasant smells by analyzing ingredients and their contribution rates through various scientific smell analysis techniques and conducting sensory evaluation.

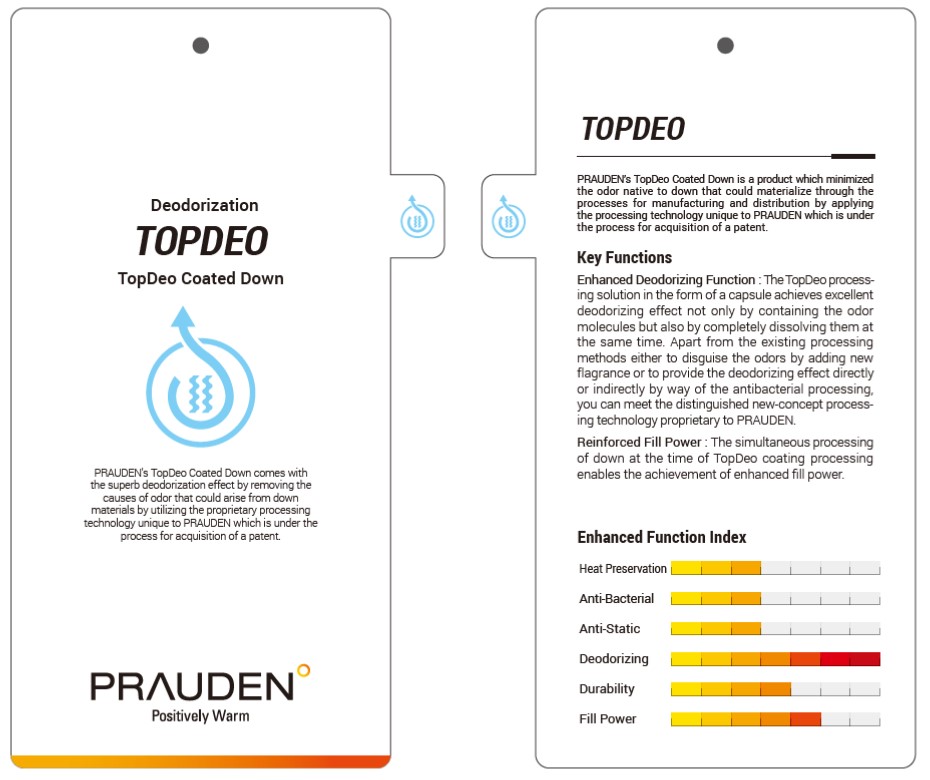

<TopDeo special processing tag>

<TopDeo special processing tag>

Check the hangtag to learn about PRAUDEN’s special processing

Down is the warmest and lightest material among natural materials. PRAUDEN has successfully developed new conceptual down while keeping its advantages and overcoming the disadvantages.

In 2017 FW Season, Black Yak will newly introduce its products applied with TopDeo special processing to consumers.

By PRAUDEN R&D Part Oh Jun-jae and Yun Ji-won