Digital Production Management System

2017-04-17

Down & feather are sorted according to the countries of origin and then processed in consideration of customer requirements such as down to feather ratio, fill power, and special processing specifications. Although such processes have been mostly mechanized, most companies manage relevant production information manually.

As various types of down & feather are processed in the same production line, manually recorded information may contain errors. To prevent such errors, PRAUDEN has established the PRAUDEN Coding System (hereinafter referred to as “PCS”) early on for systematic quality management. The PCS based on the SAP which is a global business software solution manages all data encompassing raw materials procurement, processing, delivery, and customer service. The PCS is PRAUDEN’s competitive edge that enables stable supply and quality management.

In 2017, PRAUDEN took a major step forward with the preexisting PCS through internal innovations and established a new digital production management system that allows us to monitor all information in real-time.

PRAUDEN secured quality transparency and customer convenience with the first digital production management system in the field

PRAUDEN down generally goes through raw materials procurement, raw materials processing and down production, and down delivery. The digital production management system of PRAUDEN records all data of during all processes and generates barcodes and QR codes for tracking. Therefore, all customers and PRAUDEN staff can check the sources and processes of raw materials anywhere, at any time. In particular, customers can trust and use PRAUDEN products by easily checking all elements related to down quality including country of origin and down to feather rat io. Below is a brief introduction to the system (excludes processes that are not directly related to the system including quality inspection, etc.).

Phased data management

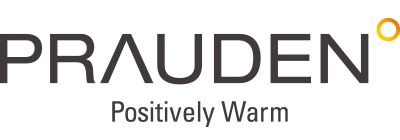

1. Arrival of raw materials

When raw materials arrive, a weight inspection is conducted on each bale and the relevant information is entered in barcodes. At this stage, the actual weight of each bale, country of origin, and down to feather ratio (based on raw materials) are recorded. As all information is automatically recorded in the SAP, we can monitor the inventory in real-time and promptly respond to customer inquiries.

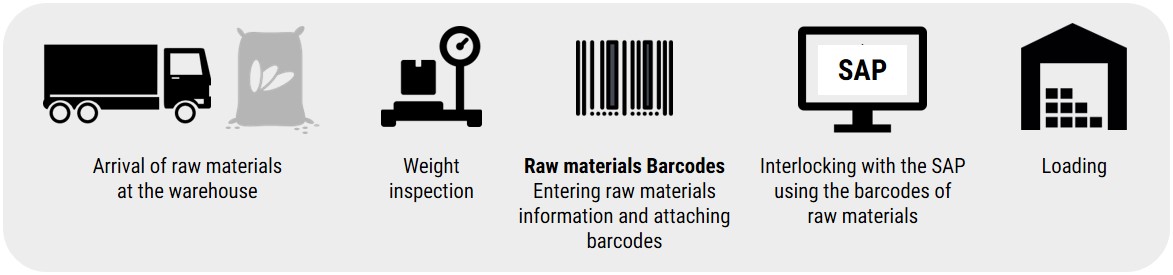

2. Down production

When a work order is received at the Head Office, the factory works on down processing. Before down production, the Head Office registers a work order containing types of raw materials and processing specifications in the SAP. The factory starts the processing according to the work order registered in the SAP. If the information entered in the SAP does not match the barcode, the system does not allow the feeding of raw materials.

After down production, down is weighed and barcodes containing raw materials information and processing history are generated. The barcodes are attached to the bales.

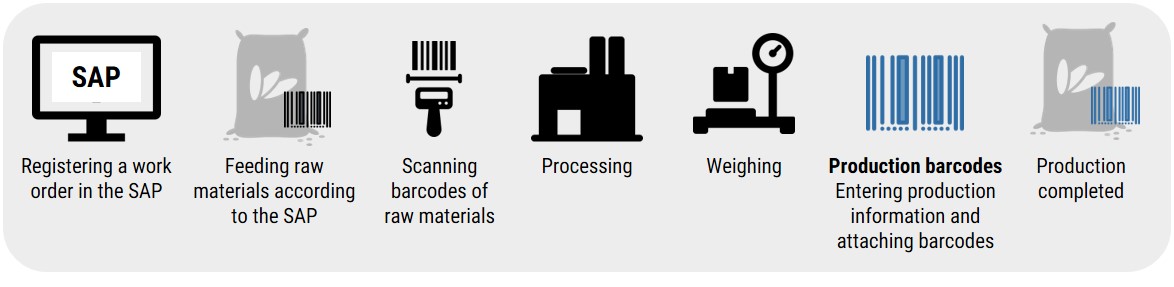

3. Down delivery

Delivery information is transferred from the Head Office to the factory via the SAP. Same as in production, factory workers can only ship out products matching the corresponding barcodes. Before delivery, delivery QR codes containing the delivery weights of down and final information are generated and attached to the bales.

4. Inspection by customers

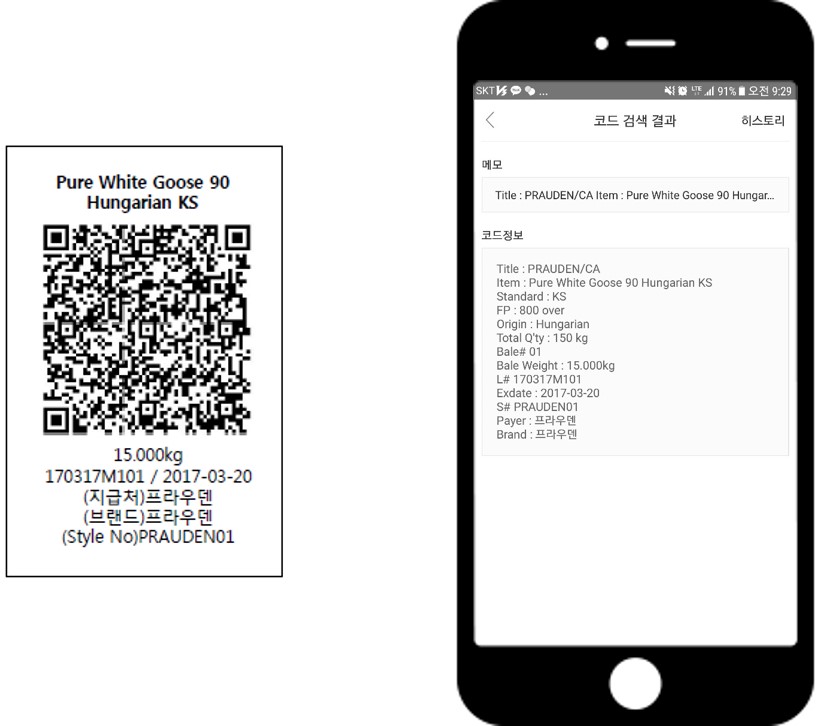

Customers can check if they have received the correct down by scanning the QR code on the bale. QR codes can be scanned on the smart phone or tablet PC. Customers use the down after comparing the information saved in the QR code with their order. They can check the following information by scanning the QR codes.

Customers can check if they have received the correct down by scanning the QR code on the bale. QR codes can be scanned on the smart phone or tablet PC. Customers use the down after comparing the information saved in the QR code with their order. They can check the following information by scanning the QR codes.

<Delivery QR code (left) and specifications recorded on the landing page (right)>

Customers can check the product names, country of origin, down to feather ratio, standards applied, fill power, and weights.

PRAUDEN established the digital production information management system for the first time in the down & feather industry, which improved productivity and enabled strict quality management. Based on this system, we provide down accurately meeting the customer’s requirements and all relevant information. This not only improves product reliability and transparency but also enables us to promptly identify the root of problems and respond to them immediately.

If you have a mobile device that can read QR codes, you can check the production history and obtain reliable information from anywhere in the world. Even in developing countries where quality internet service is not available, you can view the information saved in the QR code itself. The system is expected to improve the work accuracy and efficiency by sharing accurate information with overseas factories as well as customers.

This system has been applied to all products delivered from the Cheonan Factory and will be extended to NPA (China) and VINA (Vietnam).

By PRAUDEN R&D Part Oh Jun-jae/Yun Ji-won